A Look at Consumable vs. Non-Consumable Electrodes If You Want to Become a Welder

November 07, 2019

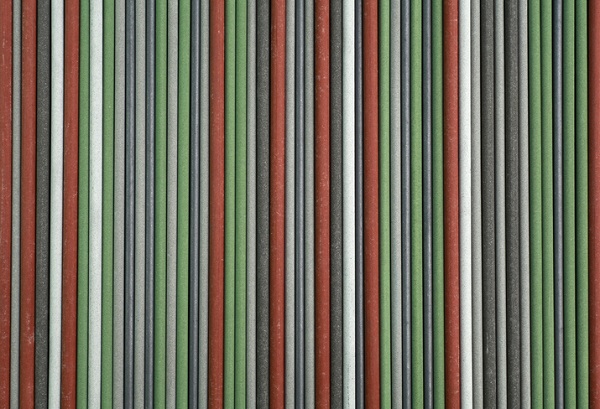

Different types of electrodes, also known as rods, are categorized based on their material, diameter, coating and whether they are consumable or non-consumable. The most common type of rods are steel, which may be mild, low alloy, or stainless, but there are also bronze, aluminum, and composite welding rods. It is part of the welder’s job to decide on which type of rods to use for different projects. The material of the core wire of a rod will depend on the type of metal being welded, also referred to as the parent material.

In order to choose the right material and type of rod, a welder must know the differences between consumable and non-consumable electrodes. Each is used for different applications and, with theoretical knowledge and hands on experience, a trained welder will know how to make these decisions to ensure quality welds.

First: a Few Basics of Welding Training

Before getting into the specifics of consumable and non-consumable electrodes it is important to set up some foundational points for your welding training. An understanding of what flux covering (or coating) is along with what a weld pool is, will give you a greater understanding of the main differences between consumable and non-consumable electrodes.

Flux coating is a layer of chemicals that covers the rod and burns off during welding. This produces an inert gas that protects the weld pool and solid metal from atmospheric contamination. Oxygen will weaken the bond of your joint and impurities in the weld pool can also cause problems. Typically, though not always, consumable rods have flux coating. Non-consumable electrodes usually do not, meaning they require the use of shielding gases.

The weld pool is the small coin-shaped part of a weld where the base metal is at its melting point. This is where a welder will either use filler material, in the case of non-consumable electrodes, or not use filler in the parent materials requiring consumable electrodes.

Consumable Electrodes

The key characteristics of consumable electrodes are the following: they have lower melting points, they are usually used in metal inert gas (MIG) welding, they are typically made of mild steel or nickel steel and they are used in arc welding. The lower melting point means that they melt away, or are consumed as the welder works. This also means that they have to be replaced on a regular basis.

There are four types of consumable electrodes if you are considering flux coating and they range from bare (no flux coating) to heavily coated. While there are even more variations in terms of the types of coating that may be used, overall, it is worth noting that consumable electrodes have fewer industry applications.

Non-Consumable Electrodes

As indicated by the name, non-consumable electrodes do not melt away in the process of welding. As a student in welding school you should know that non-consumables are made from materials with higher melting points. These materials include tungsten, carbon and graphite and although these materials will not be consumed during the weld, the rods may lose length due to vaporization and oxidation.

When using non-consumable electrodes a filler metal is necessary to make the weld pool. Shielding gases that would normally come from flux coating are also required to protect the welding area. Another factor to consider is that tungsten electrodes are more expensive than carbon or graphite electrodes. However, the choices you make will likely depend mainly on the parent materials.

Want to learn how to become a welder?

Contact North American Trades Schools to get started!