Category: Skilled Trades

3 Qualities Any Commercial Electrician Should Have After Electrician School

March 16, 2021

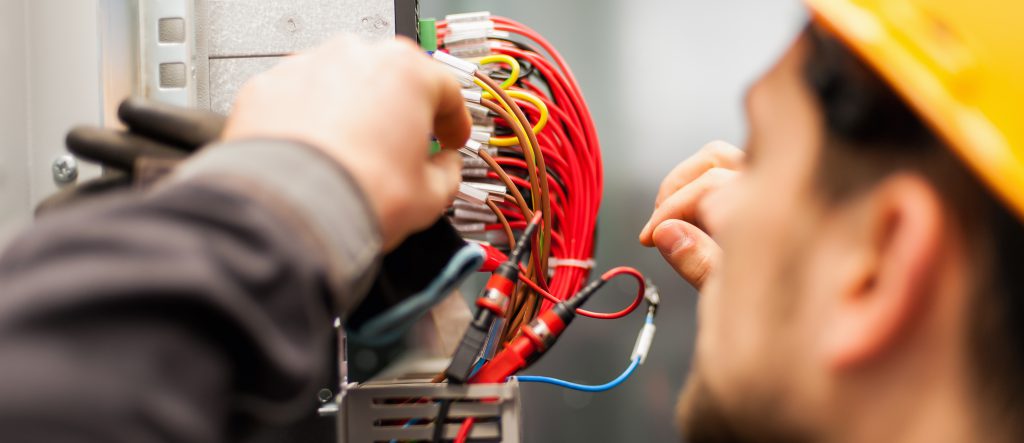

Commercial electricians install electrical systems and wiring within commercial buildings. Their work requires extreme precision and attention to detail–as well as extensive knowledge of electrical systems, codes, electrical standards and guidelines, and more. Commercial electricians often face the complex task of installing and maintaining extensive electrical systems for structures, such as: shopping malls, office complexes, restaurants, and other buildings. These electricians have difficult, and at times, dangerous jobs. Their ability to succeed in their field is made possible through a few key personal qualities.

If you’re interested in a career as a commercial electrician, exploring the qualities below can help you to gain a better grasp of what this profession requires.

1. Problem Solving Capabilities are Important for Those with Commercial Electrician Training

Installing and maintaining the electrical systems and components of a commercial complex can be a complicated task. During a typical job, commercial electricians will have a diverse range of responsibilities. Commercial complexes often have a greater need for efficient electrical systems due to the fact that businesses often use more electricity for communication and general operation. For commercial electricians, navigating the installation of these complex systems requires the ability to problem solve.

Commercial electricians will encounter unexpected challenges on-site, and must be able to come up with creative solutions to problems. Whether it’s determining how to install the number of outlets necessary to meet a business’s needs, or mapping out convenient placement of electrical wiring, professionals with commercial electrician training benefit from being great problem solvers.

2. Electrical Experience and Expertise

Typically, the electrical requirements of commercial complexes are much more demanding and extensive than those of residential buildings. These buildings are larger, consume more electricity, and have greater servicing needs than other structures. Thus, the electricians who perform installations and maintenance for commercial complexes must possess the electrical knowledge and expertise necessary to safely and efficiently meet a project’s needs.

At the North American Trade Schools, electrician college students have access to hands-on training in the lab, which equips them with valuable knowledge and experience in a variety of electrical topics. Their training qualifies them to move on to an apprenticeship, where they continue to build skills through experiential experience. When their training is complete, students will be equipped with the practical knowledge necessary to prepare them for a successful career as a commercial electrician, where they can apply their skills in the field.

3. Commercial Electricians are Dependable

Electricians in all industries have a large amount of responsibility. They are the ones relied upon to plan for and install electrical systems, conduct inspections, and determine the cause of breakdowns or other electrical issues. Businesses and contractors rely on commercial electricians to get the job done right–as a mistake could enhance the risk of electrocution or even fire.

The extent of a commercial electrician’s responsibilities requires that these professionals are extremely dependable. Commercial electricians must be responsive to the needs of the team they are working with, making themselves available to fix problems when they arise. Dependable commercial electricians are better informed about what’s happening on site, and their dedication is reflected in the quality of their work and the efficiency of a structure’s electrical systems.

Are you interested in attending electrician school?

Explore programs with the North American Trade Schools today.

Welding, while a safe profession when the correct precautions are taken, involves many risks and hazards. Welders can work with high temperatures, gases and fumes, electrical voltage, sparks, and ultraviolet rays. In order to protect themselves against explosions, burns, fumes, eye damage, and more, welders must ensure that they are following safety best practices. If you’re thinking about becoming a welding operator, make sure that you’re aware of these safety tips in order to ensure that you’re always staying safe on the job.

Welding, while a safe profession when the correct precautions are taken, involves many risks and hazards. Welders can work with high temperatures, gases and fumes, electrical voltage, sparks, and ultraviolet rays. In order to protect themselves against explosions, burns, fumes, eye damage, and more, welders must ensure that they are following safety best practices. If you’re thinking about becoming a welding operator, make sure that you’re aware of these safety tips in order to ensure that you’re always staying safe on the job.

Those with a Welding Career Should Stick to a Routine–Before, During, and After a Welding Job

Before beginning any welding job, it’s important to cover all your bases to ensure that the area you’re working in is as safe as possible. Welding operators should always review their operating manual, which contains all the safety information and regulations provided by the manufacturer.

Make a list or mental note of things to check for before, during, and after your welding project. If you’re in a welding career, check for any hazards before beginning your project, such as flammable materials nearby. Make sure to check the equipment you’re working with. Is it functioning properly? Could you injure yourself accidentally on nearby equipment? Do you know where everything is for easy access? During your project, stay mindful of surfaces or surrounding materials that could be hot and should be avoided. After you’ve finished the job, make sure to clean up your workspace. Return all equipment, and ensure that there’s no possibility of a fire occurring.

Wear the Right PPE (Personal Protective Equipment)

Welders should never begin a project without wearing the right PPE (personal protective equipment). Your PPE will keep you injury-free and protect you from burns, vibrations, and exposure to ultraviolet rays. Your PPE should consist of cotton clothing treated with flame-resistant properties. Wear leather boots that cover your ankles, and never roll up your sleeves or cuffs or unbutton your shirt, which can allow skin to become exposed to sparks or enable sparks to catch in cuffs or pockets, where they can burn. When welding, always wear safety glasses with side shields to protect your eyes from debris and sparks, and always wear protective gloves. Wear a helmet equipped with the proper shade lens for your project to prevent exposure to arc rays, which can cause painful injury to eyes and skin.

Ensure You’re Using Proper Ventilation

If you’ve attended welding school, you’ll understand the dangers of overexposure to welding fumes. In order to avoid this, make sure that your workspace is equipped with proper ventilation systems to remove fumes and gases from the breathing zone. Adequate ventilation will depend on the type of base metal and rod you’re using during your welding project, as these contain different levels of metal oxide compounds. It’s likely that your employer will provide a ventilation system, but make sure to wear a respirator unless you’re sure that exposure levels are below safety limits.

Take Precautions to Prevent Fires

Welding arcs can pose a lot of danger due to the intense heat and sparks they create. Make sure you remove all flammable materials from your work environment or cover them with a fire resistant material before beginning. Check to make sure you know where the fire extinguishers and alarms are located, check that they are functioning, and identify the fire exit nearest to you. If welding near flammable materials, have someone keep an eye on the sparks. Always stay in a work area for at least 30 minutes after finishing a project to ensure that the sparks created will not start a fire.

Stay Dry to Prevent Electric Shock

Welders should take great precautions to ensure that electric shock doesn’t occur, as shock can result in injury or death in serious cases. Electric shock can occur by contact with an electric circuit, which commonly occurs when two metal objects that have voltage between them are touched, or when secondary shock is experienced from a welding circuit. Always inspect electrode holders for damage before starting a project, checking that they are properly insulated, which ensures that the welder will not touch the hot parts within the electrode holder. Be sure to wear gloves and PPE that is completely dry when handling electrodes or electrode holders.

Are you interested in attending welding college?

Check out the North American Trade School’s program options for future welders.

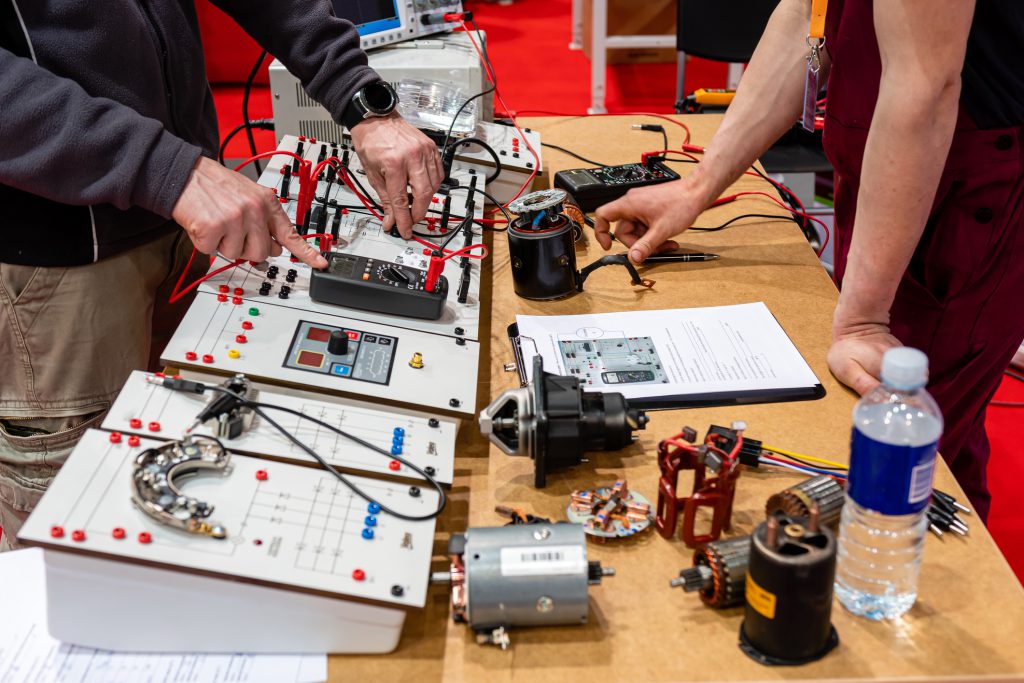

4 Things for Electrician School Students to Know About Electric Motors

October 15, 2020

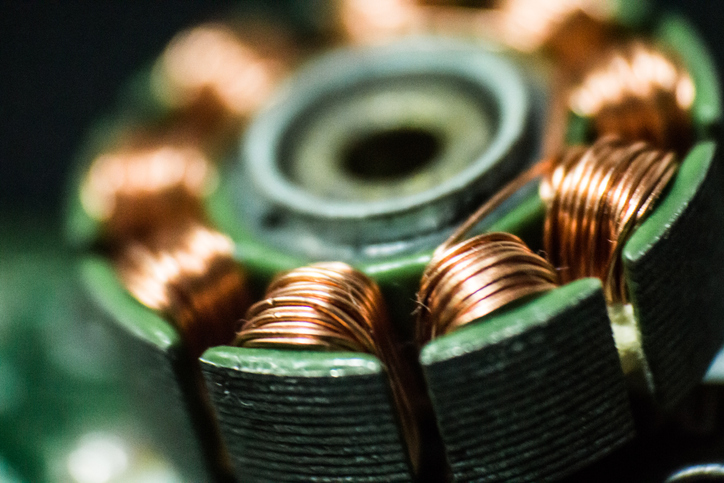

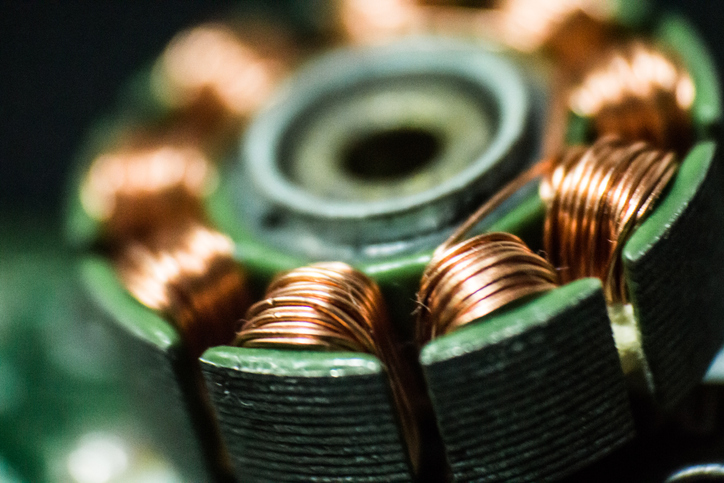

They’re found in appliances and toys throughout your house: remote control cars, electric can openers, computers, washing machines, electric mowers, electric toothbrushes, and much more. In fact, the electric motor might just be one of the most useful electrical inventions since Benjamin Franklin discovered electricity!

Most electric motors have a four-pole permanent magnet motor with double insulation design that runs at 120 volts. They work by adding electricity at one end, which sends a jolt to rotate the metal axle at the other end to power whichever machine the motor lives in.

What else should you know about these incredibly useful and common motors? Here are four things to keep in mind about their design and functioning.

1. They Work Using Electromagnetism

Those attending electrician school will learn electrical motor theory. When power is added, what really happens is that current flows through the motor’s coil to generate a magnetic force. One side of this force will flow in the direction the magnetic field is heading in, while a force generated on the other side of the housing will begin flowing the other way. Rotation on the armature thus happens, as an up-and-down action is created.

Most small household appliances like blenders and coffee grinders are run by a universal electric motor. This motor uses an electromagnet to take its energy from the DC or AC power feed, as the motor can be either AC or DC-powered.

2. Dynamic Braking Is Used for Safety

Most electric motors handle safety with the addition of a dynamic braking feature, also known as rheostatic braking. Located inside the circuitry of the motor, handle switch, and wire harness, the dynamic brake is activated upon the handle switch’s release. After the handle switch moves into the off position, the motor is brought to a complete halt.

There are also two other types of electric braking commonly found in the DC motor. Plugging—also called reverse current braking—gives greater braking torque than dynamic braking, and is more commonly used in larger machines such as printing presses and elevators. Regenerative braking is used when there is heavy inertia on the load on the motor, as one would find with an electric train.

3. Improper Maintenance Is the Leading Cause of Malfunction

Many electric motors will last longer if given the right level of care. Electric mowers and HVAC units are good examples of things needing regular maintenance, due to their exposure to grass, dirt, dust, and other contaminating elements.

At least once a year, an electric motor that can be contaminated in this way should be inspected and have all of its parts cleaned. This helps to avoid incidences of overheating by removing anything that may be clogging the filter and air cooling system of the machine.

4. Specialized Electrician Training Is Helpful for Attending to Repairs

To diagnose a problem with an electric motor, a technician with electrician training should start by using a digital multimeter to assess the components. Once a problem has been identified, the motor must often be disassembled to proceed with repairs. From there, the parts can be assessed for damage, corrosion, rust, or other contaminants. Brushes will often need to be replaced, along with any damaged parts, but rust and corrosion can usually be cleaned off with a wire brush.

Electric motors are an essential part of modern life, used to power all kinds of machinery in and out of the household. Most of the designs on these kinds of motors are built to last, and will tend to have a good lifespan as long as they are well-maintained. When problems occur, people rely on the specialist knowledge that those trained on electric motor theory can provide.

Interested in learning more about electric motors by receiving professional training at an electrician college?

Contact North American Trade Schools today for more information on our Construction & Maintenance Electrician Pre-Apprenticeship diploma program!

They’re found in appliances and toys throughout your house: remote control cars, electric can openers, computers, washing machines, electric mowers, electric toothbrushes, and much more. In fact, the electric motor might just be one of the most useful electrical inventions since Benjamin Franklin discovered electricity!

Most electric motors have a four-pole permanent magnet motor with double insulation design that runs at 120 volts. They work by adding electricity at one end, which sends a jolt to rotate the metal axle at the other end to power whichever machine the motor lives in.

What else should you know about these incredibly useful and common motors? Here are four things to keep in mind about their design and functioning.

1. They Work Using Electromagnetism

Those attending electrician school will learn electrical motor theory. When power is added, what really happens is that current flows through the motor’s coil to generate a magnetic force. One side of this force will flow in the direction the magnetic field is heading in, while a force generated on the other side of the housing will begin flowing the other way. Rotation on the armature thus happens, as an up-and-down action is created.

Most small household appliances like blenders and coffee grinders are run by a universal electric motor. This motor uses an electromagnet to take its energy from the DC or AC power feed, as the motor can be either AC or DC-powered.

2. Dynamic Braking Is Used for Safety

Most electric motors handle safety with the addition of a dynamic braking feature, also known as rheostatic braking. Located inside the circuitry of the motor, handle switch, and wire harness, the dynamic brake is activated upon the handle switch’s release. After the handle switch moves into the off position, the motor is brought to a complete halt.

There are also two other types of electric braking commonly found in the DC motor. Plugging—also called reverse current braking—gives greater braking torque than dynamic braking, and is more commonly used in larger machines such as printing presses and elevators. Regenerative braking is used when there is heavy inertia on the load on the motor, as one would find with an electric train.

3. Improper Maintenance Is the Leading Cause of Malfunction

Many electric motors will last longer if given the right level of care. Electric mowers and HVAC units are good examples of things needing regular maintenance, due to their exposure to grass, dirt, dust, and other contaminating elements.

At least once a year, an electric motor that can be contaminated in this way should be inspected and have all of its parts cleaned. This helps to avoid incidences of overheating by removing anything that may be clogging the filter and air cooling system of the machine.

4. Specialized Electrician Training Is Helpful for Attending to Repairs

To diagnose a problem with an electric motor, a technician with electrician training should start by using a digital multimeter to assess the components. Once a problem has been identified, the motor must often be disassembled to proceed with repairs. From there, the parts can be assessed for damage, corrosion, rust, or other contaminants. Brushes will often need to be replaced, along with any damaged parts, but rust and corrosion can usually be cleaned off with a wire brush.

Electric motors are an essential part of modern life, used to power all kinds of machinery in and out of the household. Most of the designs on these kinds of motors are built to last, and will tend to have a good lifespan as long as they are well-maintained. When problems occur, people rely on the specialist knowledge that those trained on electric motor theory can provide.

Interested in learning more about electric motors by receiving professional training at an electrician college?

Contact North American Trade Schools today for more information on our Construction & Maintenance Electrician Pre-Apprenticeship diploma program!

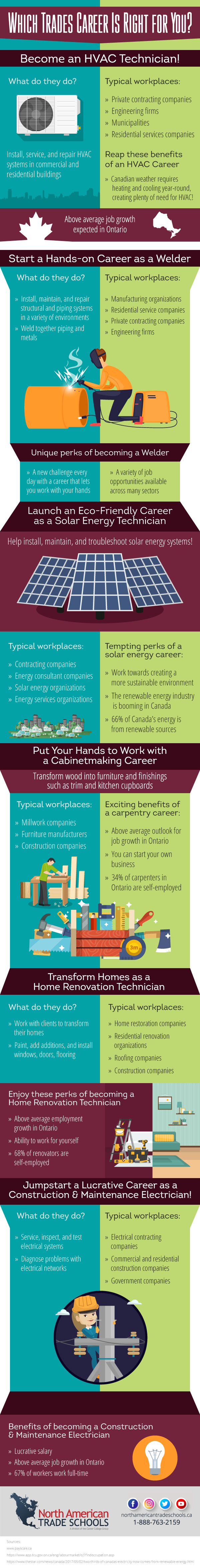

There’s no doubt that the trades are an excellent path for individuals looking for a stimulating and reliable career that allows them to work with their hands and make a good income. If you’ve already determined that you want to work in the trades, the next step is to determine which particular trades career is ideal for you, so you can enroll in the right program at trades school!

There are plenty of exciting options available in the trades, from becoming a carpenter or cabinet maker to starting an electrician or HVAC career. Curious to learn more? Read our infographic below for an introduction to promising trades careers, so you can determine which career is right for you!

Which Trades Career Is Right for You?

Become an HVAC Technician!

What do they do?

- Install, service, and repair HVAC systems in commercial and residential buildings

Typical workplaces

- Private contracting companies

- Engineering firms

- Municipalities

- Residential services companies

Reap these benefits of an HVAC Career

- Canadian weather requires heating and cooling year-round, creating plenty of need for HVAC!

- Above average job growth expected in Ontario

Start a Hands-on Career as a Welder

What do they do?

- Install, maintain, and repair structural and piping systems in a variety of environments

- Weld together piping and metals

Typical workplaces

- Manufacturing organizations

- Residential service companies

- Private contracting companies

- Engineering firms

Unique perks of becoming a Welder

- A new challenge every day with a career that lets you work with your hands

- A variety of job opportunities available across many sectors

Launch an Eco-Friendly Career as a Solar Energy Technician

What do they do?

- Help to install, maintain, and troubleshoot solar energy systems

Typical workplaces

- Contracting companies

- Energy consultant companies

- Solar energy organizations

- Energy services organizations

Tempting perks of a solar energy career

- Work towards creating a more sustainable environment

- The renewable energy industry is booming in Canada

- 66% of Canada’s energy is from renewable sources

Put Your Hands to Work with a Cabinetmaking Career

What do they do?

- Transform wood into furniture and finishings such as trim and kitchen cupboards

Typical workplaces

- Millwork companies

- Furniture manufacturers

- Construction companies

Exciting benefits of a carpentry career

- Above average outlook for job growth in Ontario

- You can start your own business

- 34% of carpenters in Ontario are self-employed

Transform Homes as a Home Renovation Technician

What do they do?

- Work with clients to transform their homes

- Paint, add additions, and install windows, doors, flooring, and more

Typical workplaces

- Home restoration companies

- Residential renovation organizations

- Roofing companies

- Construction companies

Enjoy these perks of becoming a Home Renovation Technician

- Above average employment growth in Ontario

- Ability to work for yourself

- 68% of renovators are self-employed

Jumpstart a Lucrative Career as a Construction & Maintenance Electrician!

What do they do?

- Service, inspect, and test electrical systems

- Diagnose problems with electrical networks

Typical workplaces

- Electrical contracting companies

- Commercial and residential construction companies

- Government companies

Benefits of becoming a Construction & Maintenance Electrician

- Lucrative salary

- Above average job growth in Ontario

- 67% of workers work full-time

Sources:

https://www.app.tcu.gov.on.ca/eng/labourmarket/ojf/findoccupation.asp

Have you been considering enrolling in a training program for quite some time? If so, it’s the perfect time to stop making excuses and start making progress!

Trade school is an excellent option for students looking for an affordable and efficient education that will lead to a lucrative and secure career with great job satisfaction. There are so may trade and construction careers available in Canada, within many different industries, that you’re bound to find your ideal fit in the trades.

The first step towards starting your career, though, is enrolling in a training program so you have the knowledge you need to succeed. If you’re hesitant to make the leap, keep reading to discover some great excuse-proof reasons why you should take control of your future and enroll in trade school!

Excuse-proof Reasons to Enroll at a Trade School

You can’t argue with these great reasons to enroll in trade school!

Receive Highly Relevant and Applied Training

- Learn in a hands-on environment

- Begin practicing your new skills right away

- Apply all the knowledge you gain directly to your career

A Variety of Exciting Career Options

You can study to become a:

- Welder

- HVAC Technician

- Solar Energy Technician

- Cabinetmaker

- Home Renovation Technician

- Construction & Maintenance Electrician

- Electrical Technology Technician

- And more!

A Shorter & More Affordable Program than a Traditional University Degree

- Skip a 4-year degree

- Begin working quickly after graduation

- Financial options, like the following, help students pay for their studies:

- Student Lines of Credit

- Ontario Student Assistance Program (OSAP)

- Second Careers

- RESP

- Lifelong Learning Plan

- Employment Ontario

- Monthly Payment Plan

The Trades Are Booming Across Canada

- 6 million skilled job openings by 2021

- Trades workers make an hourly wage that’s about 6% higher than other occupations

Begin a Career That Aligns with Your Passions

- Train for a career you’re excited about

- Work in a hands-on environment

- See the fruits of your labour

- Have the opportunity to open your own business

Fun fact: Professionals working in the trades report higher job satisfaction

Receive Personalized Help Finding Your Ideal Career

- Learn how to create an effective cover letter, resume, and portfolio

- Benefit from private job listings through your college

- Choose a school with a Hire a Grad program

Experienced Instructors

- Receive career advice from experienced industry professionals

- Learn from knowledgeable and passionate instructors

Sources:

https://www.ontariocolleges.ca/colleges/paying-for-college

https://business.financialpost.com/executive/making-a-university-degree-pay-off

https://www.macleans.ca/work/jobs/the-future-of-jobs-in-canada/

4 Interview Tips That Can Help You Launch Your Electrician Career in Construction

July 16, 2019Are you hoping to start a career as a construction electrician? Great! Becoming a construction electrician means stepping into a hands-on career that is anything but your typical 9-5 office job.

Progressing along this career path, however, still means that you need to prepare for the interview process. Fortunately, there are plenty of tips and tricks you can use to approach your interview with confidence.

Here are a handful of tips for when you’re about to step into an interview.

1. Be Ready to Encounter Basic Questions During Your Interview

Employers looking to hire electricians and apprentice electricians—including in construction—may sometimes ask you basic questions like “What is the difference between a breaker and a fuse?”. Should they do this, it’s to filter out the candidates who have the best foundational knowledge of the profession from the ones who don’t. If necessary, brush up on your overall knowledge of electrician-related concepts before your interview so you go in able to explain them in as much detail as possible.

2. Prepare for Questions About Challenges and Troubleshooting

While being interviewed, you can expect employers to be curious about your problem-solving abilities. After all, problem-solving is important to this career path. Therefore, you might face questions about how you’d handle unexpected situations, and perhaps the specific process through which you would try to solve the problem.

They may also ask questions like, “What was the biggest challenge you’ve faced so far in your career?” or “What was the biggest mistake you’ve made at a job, and how did you atone for it?” Either way, interviewers will want to know how you overcame these obstacles.

3. Be Ready for Construction-Specific Questions

A number of electricians work in specialized fields, and construction electricians are definitely among them. As a result, you can expect questions specific to construction. For example, they might ask you what you love most about the field, or why you’re interested in the position. They may also ask you what you learned during your electrician training, and what you ultimately took out of the experience. In any case, these employers are going to want to know how your training and experience makes you an ideal fit for the position.

4. Answer Questions Honestly, and Be Yourself

Whether the questions are technical in nature, or if they’re simply about your past experiences in the field, be honest and descriptive in answering them. Even if you flub a question or wind up not getting the job, it’s still great practice for future interviews you may get later in your career as a construction electrician. Above all else, smile, be enthusiastic, and be respectful and professional throughout the process! After all, if you want to become a maintenance electrician, you can’t forget the basic tenets of how to ace a job interview in any industry.

Looking to start your electrician career in construction?

Contact North American Trade Schools to find out about our Construction & Maintenance Electrician Pre-Apprenticeship diploma program!

Think You Need University for a Well-Paid Job? Why Trade School May Be a Better Option

May 14, 2019If you’re like many people, you may believe that if you want a high-paying job, you need to go to university. This belief has been repeated so often that for some people it seems almost self-evident. Fueling it is the fact that for some there is a stigma against the trades, with trades work unfairly seen as low-skilled, low-paid, and dirty, which couldn’t be further from the truth.

What you may not realize is that you don’t need university for a well-paying job. In fact, if it’s a hefty pay cheque that you’re after, you may be better off going into the trades. Let’s take a look at why trade school could be a better option if you’re looking to pursue an in-demand and well-paid career.

Trade School Takes a Lot Less Time Than a University Degree

If you want to pursue a university degree, chances are you’re going to be in school for at least 3 to 4 years. For some professions like law, architecture, and medicine, the amount of time you’ll spend in school could be much longer. During that time, you’ll likely be accumulating student debt and you’ll typically only have limited opportunities to work while studying.

When attending a trade school, however, the situation is completely different. You’ll be able to finish your studies in less than a year and then enter the job market. Furthermore, during your apprenticeship after trade school you’ll continue to learn, but you’ll also be getting paid. That can help you avoid the years of student debt that university students often acquire.

Trade school takes less time than university and allows students to start earning faster

The Trades Are Among the Most In-Demand Jobs in Canada

If you want a career that pays well, you’ll usually need to get one that is in demand. When it comes to the trades, it’s hard to overstate just how severe of a skills shortage there is in Canada. The unemployment rate in Canada is currently at a four-decade low, and the jobs that are in most demand are in the trades.

In fact, a recent survey found that 41 per cent of employers say they can’t fill open jobs, and the ones that are among the hardest to fill are in the skilled trades. In fact, according to that same survey, “One in four employers says filling skilled trades roles is harder this year than last.” Employers say the main reason they can’t fill those jobs is simply because there aren’t enough applicants. So, if you’re looking to get hired fast, then a trade may be for you.

The trades are among the most in-demand jobs in Canada

With a Career in Construction, You Can Earn a Good Salary

Of course, the big question you probably have is which is more likely to lead to a better paying job: the trades or a university degree. According to Statistics Canada, men with an apprenticeship certificate (in other words, those working in the trades) earn a median salary of $72,955, which is ahead of those with college diplomas or just high school qualifications. While that’s still 11 per cent lower than the median earnings for men with bachelor degrees, it’s important to keep in mind that that gap looks much smaller when you consider the high student debt university graduates accumulate along with the fact that trades people can usually enter the workforce much faster.

Plus, in some trades the average salary is higher than the average salary for degree holders. The median salary for men who work as electricians, for example, is $84,016, higher than the median $82,082 that men with bachelor’s degrees earn. In other words, if you’re after a well-paid job, then construction school may be a better fit for you than university.

Do you want a career in construction?

Contact North American Trade Schools to learn about our programs.

How to Become a Certified Electric Motor System Technician After Electrician School

March 26, 2019Electric motor system technicians maintain and repair electric motors. Many employers and unions in Ontario require electric motor system technicians to have a Certificate of Qualification. Having certification is often viewed as a major asset and many employers are willing to pay a higher salary to those who have it.

If a career as an electric motor system technician sounds appealing to you, you should know what steps are involved in becoming certified. Certification is offered through the Ontario College of Trades, which sets out the following pathway to certification.

Electric Motor System Technician Apprentices Must Complete 8,000 Hours of Training

To become a certified electric motor system technician, you will need to complete a total of 8,000 hours of apprenticeship training. Of that, 7,520 hours consists of on-the-job training while just 480 hours is in-class technical training. During the on-the-job training portion, you will be employed by a sponsor who will teach you the skills you need to eventually become a certified electric motor system technician. To set up the in-class training component, you’ll need to contact your local apprenticeship office.

Electric motor system technician certification requires 7,520 hours of on-the-job experience

Once you complete these 8,000 hours of training, you can receive your Certificate of Apprenticeship. Then, you can take the Certification of Qualification exam, which allows you to become a journeyperson. Becoming a journeyperson means you can command a higher salary and even sponsor electric motor system technician apprentices yourself. The Certification of Qualification is an Interprovincial Red Seal Certification, meaning it is recognized across Canada.

Electrician School Can Help You Complete the On-the-Job Portion of Certification

Given the high number of on-the-job hours you need for certification, work experience is arguably the most important aspect of becoming a certified electric motor system technician. To prove your work experience, you will complete a Schedule of Training with your sponsor during your apprenticeship. This Schedule of Training includes a list of on-the-job skills that you must master, such as being able to set up and operate machines and being able to demonstrate safe working practices.

Going to electrician school can help prepare you to succeed when completing the skill sets in your Schedule of Training. For example, during electrician college, you will learn how to use electrician hand tools, which can help you complete the component of your Schedule of Training that requires apprentices to display proficiency in maintaining and using hand and power tools and equipment.

Learning how to use hand tools during electrician training can help you meet certification requirements

Furthermore, completing electrician training gives you a big boost when looking for the employers to sponsor you during your apprenticeship. That’s because employers highly value the skills that you will have learned in classes, so they are more likely to be eager to bring you onto their teams. A reputable electrician school will also have established relationships with employers and can help you land a job faster, which means you’ll get started on your work experience component towards electric motor system technician certification quicker.

Are you ready to take the first step towards an electric motor system technician career?

Contact North American Trade Schools to find out more about electrician training.

Are you considering a career as a maintenance electrician? A big part of the job is servicing electrical equipment and diagnosing problems in a home’s wiring. Particularly when working in older homes, electricians often find electrical problems that, if ignored, can become serious safety hazards.

While there’s a broad range of electrical issues that you may encounter once you become an electrician, the following are among the most common examples.

A Lack of Electrical Outlets is a Potential Safety Hazard

Houses built today generally have electrical outlets that are placed no more than 3.6m away from each other. Older houses, however, may have far fewer outlets than people need, which can lead to two potential hazards. First, the homeowners may have to rely on extension cords, which are hazardous if used improperly. For example, joining multiple extension cords together, attaching them to the floor or wall with staples and powering many appliances with a single cord are all fire hazards that you are more likely to see in homes with too few outlets.

Improper use of extension cords increases the risk of blown fuses and fires

Secondly, a shortage of outlets may prompt some homeowners to overload individual outlets with too many appliances, which can lead to blown fuses and even fires. Once you graduate from your construction and maintenance electrician program, you’ll likely have clients who would like you to install additional outlets into their homes.

Watch for This Sign Indicating That a Home’s Wiring May be Ungrounded

Once you begin your electrician career in construction, it’s important to be on the lookout for whether a home has two-holed or three-holed outlets. A lack of three-holed outlets could indicate a serious safety hazard with a home’s wiring: a lack of grounding. The third arch-shaped hole in modern outlets is designed to connect appliances to the grounding wire. Experts know that the grounding wire is essential because, in case of a short circuit, it ensures the electricity is sent to the earth rather than through a person’s body. While new homes are built with a grounding wire, older homes that lack this safety feature will require some major rewiring work.

Ensure Homes Have Enough Ground Fault Circuit Interrupters After Construction School

A ground fault circuit interrupter (GFCI) is a simple but essential safety device for outlets that are at risk of coming into contact with water, such as outlets located in washrooms, kitchens or outdoors. A GFCI automatically trips if it detects a discrepancy between the electricity flowing in and out of an outlet, as this discrepancy could indicate a person is being electrocuted. By tripping the circuit, that electricity is redirected through the grounding wire into the earth.

You can tell an outlet is GFCI-equipped if it has a ‘Test’ and ‘Reset’ button

Electrical and building codes, which you will learn about at construction school, now mandate where GFCI-equipped outlets must be located in new homes. The Canadian Electrical Code, for example, requires that any outlet located within 1.5m of a sink, outside within 2.5m of the finished grade, or at other points where it is at risk of coming into contact with water, be equipped with a GFCI. If an outlet contains two buttons which read ‘Reset’ and ‘Test’ then it is GFCI-equipped. If it isn’t GFCI-equipped and is close to a water source, it should be upgraded.

Are you ready to become a construction electrician?

Contact North American Trade Schools today to learn more about our programs!

Considering Electrician Training? 4 Common Causes of Electric Motor Breakdowns

January 01, 2019If you’re considering electrician training, one of the career paths you could pursue after graduation includes electric motor analysis and repair. Electric motors can be found in many places—hair dryers, air conditioners and even huge cargo ships all function with electric motors. When an electric motor breaks down, it’s the job of an electric motor analyst to get it up and running again.

If working with electric motors sounds exciting to you, you may be interested in learning a little about the main causes of electric motor breakdowns. Read on to learn more.

1. How Heat Affects Electric Motors: What Electrician Training Will Teach You

Excessive heat can be extremely damaging to electric motors because it increases wear and tear on the motor’s parts, particularly on the motor’s insulation. Once the insulation has deteriorated, the motor will fail. Overheating can be caused by a number of factors, such as power surges, contamination and simply operating the motor in a very warm environment. In fact, you’ll see that many of the issues causing electric motor breakdowns generally lead to overheating.

Once you’ve completed your electrician training and begin working in the field, you’ll likely find that most electric motor breakdowns you’ll be tasked with repairing will relate to excessive heat.

After electrician college, you’ll encounter many electric motor breakdowns linked to heat

2. Humidity and Moisture Can Corrode the Insulation of an Electric Motor

Humidity or moisture of any kind is not good for electric motors. When moisture gets into the motor, it may cause parts of the motor to corrode more rapidly than they would in a dry environment. Humidity, for example, can corrode insulation and if that corrosion is not stopped then the insulation may become so damaged that the entire motor breaks down.

3. Electric Motors Should Not Operate Above their Limits

Every electric motor has a maximum capacity in terms of the amount of electrical current it can carry. A surge in electricity to the motor can cause both overheating and overcapacity, which reduces the lifespan of a motor’s parts and may eventually lead to a breakdown. Electrician college grads know that a current protector, such as a circuit breaker, is the best way to prevent an electrical overload from damaging an electrical motor, since this will automatically shut down the motor when a surge occurs.

4. Dirt, Dust and Other Forms of Contamination Can Increase Wear and Tear

Electric motors can easily become contaminated with dirt, dust, grease and other particles. After you complete your electrician certification, you’ll likely work on many electric motors that have experienced problems because of excessive dirt and dust. Some contaminants will simply wear down or corrode the motor’s parts or make it run less efficiently. Others may be electrically conductive, which means that they can interfere with the electric current that is running through the motor. Contaminants can also block airflow to the engine, preventing the engine from cooling down and forcing it to overheat. Regular maintenance and upkeep is the best way to reduce contamination-related breakdowns.

Dirt and other contaminants can cause an electric motor’s parts to wear down and corrode

Are you interested in attending electrician college?

Contact North American Trade Schools to learn more about our programs!